Galvanized Steel Sheet

Galvanized Steel Sheet

Galvanized steel plate is divided into ordinary electrolytic plate and fingerprint resistant electrolytic plate. The fingerprint resistant plate is added to the ordinary electrolytic plate on the basis of a fingerprint resistant treatment, can resist sweat, generally used in the parts without any treatment, the brand is SECC-N. Ordinary electrolytic plate and phosphating plate and passivation plate, phosphating is more commonly used, the brand is SECC-P, commonly known as p material. Passivated plates can be oiled or unoiled.

Example:

Hot dip zinc steel plate (SGCC) has one advantage over electric galvanized steel plate (SECC), SECC bending and section is very easy to rust, SGCC rust resistance under the same conditions is much better. High-quality chassis usually use SECC or SGCC galvanized steel plate, the use of this material chassis steel plate color bright, metallic luster, the advantage of this steel plate is good corrosion resistance.

Electric galvanized steel plate (SECC) : uniform gray, mainly imported, fingerprint resistance, has very superior corrosion resistance, and maintains the processability of cold rolled sheet. Uses: Home appliances, computer cases and some door panels and panels.

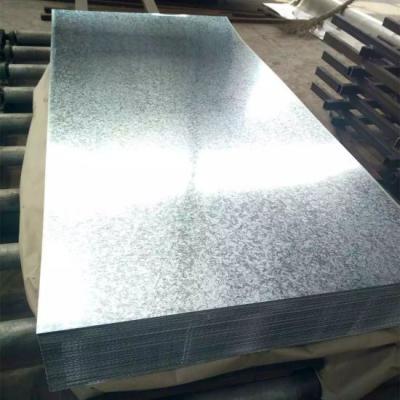

Hot dip zinc plate (SGCC) : Dip plated, bright white, small zinc flowers (difficult to see), large zinc flowers can be clearly seen hexagonal flower blocks.

Main features:

Corrosion resistance, paint resistance, formability and spot weldability.

It is widely used, mainly for small household appliances that need good appearance parts, but compared with SECC, its price is more expensive, so many manufacturers use SECC to save costs.

Divided by zinc: the size of zinc flowers and the thickness of zinc layer can explain the quality of zinc plating, the smaller the thicker the better. Manufacturers can also add fingerprint resistant treatment. Also, it can be distinguished by its coating, such as Z12, which means the total amount of double-sided coating 120g/mm.

For example:

Aluminized zinc steel plate (SGLD) : It is a multiphase alloy material containing rich aluminum and zinc. Because of the characteristics of aluminum and zinc, it has better performance than hot dip zinc steel plate (SGCC). Main features: corrosion resistance, which is much higher than SGCC; Heat resistance; Heat conduction and heat reflection; Formability; Weldability. Uses: Used in some places that require good reflection, such as the reflector plate inside the oven, the reflector plate of the electric pot. Hot dip zinc steel plate (SGCC) is general use, aluminized zinc steel plate (SGLD) is deep stamping, SGCE is super deep stamping.

INQUIRY

CATEGORIES

LATEST NEWS

CONTACT US

Contact: Michael

Phone: +86 18863527171

E-mail: Michael@Sdfhsteel.com

Add: Liaocheng Economic and Technological Development Zone, Shandong Province